There is Always a Better Way. Manufacturing Support materials for Medical Device Industry

- Ulick Stafford

- Jul 17, 2020

- 5 min read

Medical devices are ingenious inventions. They are clever devices that improve people’s lives. Replacement joints or limbs allow people to walk. Implantable pacemakers and defibrillators keep people with heart problems alive. Contact lenses allow clear vision without glasses. Stents keep blood vessels open. Various monitors check all vital signs. The range of devices and their uses is extremely numerous.

Their inventors are inspired medical people with great ideas. They envision the life or health saving idea and then design and make a prototype. These prototypes are tested and tweaked to overcome difficulties. A satisfactory version is submitted to regulatory authorities, eventually approved and launched on the first market. Subsequent market approvals and acceptance by the doctors and surgeons follows eventually. Sales growth is slow at first but can reach a very high long-lived plateau after other medical professionals have come to know and trust the product.

By the time of increased sales growth, the talented inventors have often gone to work on new projects, designing and developing the next great idea. It becomes apparent that several of the laboratory processes that were used to make and process all the components needed to make the device are not optimized for scale-up. These could be processes to make or modify components or necessary manufacturing aids.

And because the device is a regulated medical device, quality and regulatory approval is required to change the manufacturing process. The resources required to safely make these improvements - people, materials and finances, are often perceived as so costly that the change is not made. The most talented invention teams are working on the next big idea which is always seen by top management as more strategically important for the company’s future than improving current processes.

If the risk were merely financial this would be a correct rational decision. After all, if the product has a limited sales or patent life at a high sales price point there would be less benefit to optimizing its manufacturing process than developing processes for new products. However, approval and practitioner acceptance for new replacement products usually comes more slowly than planned, which extends the profitable life of most successful products considerably longer than originally expected.

Another problem with this approach is that few new products are completely new. New products often follow on from old products. Products with similar design and function are approved more easily than completely new products. It is very likely that the same manufacturing processes that were used to make the current products will be used to make the new product.

When new products are being developed, there is an excellent opportunity for optimizing and validating improved manufacturing processes. However, this opportunity is often ignored. The product developers who make small numbers of prototype devices may not have the insight into difficulties associated with increased production. Or maybe sales and marketing or senior management will baulk at any change that may imperil the launch date by even one or two months.

The most important reason that the process should be improved is that the prototype process that was scaled up is often less reliable than an optimized manufacturing process. This can lead to reduced yields that increase the quality cost, and the likelihood of a defective product going onto the market. To reduce the likelihood of the latter, extra inspections are often put in place that significantly increase the cost of manufacture and reduce production volume of good parts. And only in extreme cases such as a CAPA (corrective or preventative action initiated to solve a serious problem found in an audit or in the field), or regulatory action will a project be initiated to permanently solve this manufacturing difficulty. Then the solution implemented is often the quickest and easiest rather than the best possible.

Improving quality by eliminating defects inevitably reduces the cost of production. This is a topic explored in detail by Philip Crosby in ‘Quality is Free’. Crosby developed a 14-step process to quality improvement.

Table 1. Philip Crosby’s 14 Steps to Quality Improvement:

1: Management Commitment

2: Quality Improvement Team

3: Quality Measurement

4: Cost of Quality Evaluation

5: Quality Awareness

6: Corrective Action

7: Establish an Ad Hoc Committee for the Zero Defects Program

8: Supervisor Training

9: Zero Defects Day

10: Goal Setting

11: Error Cause Removal

12: Recognition

13: Quality Councils

14: Do It Over Again

Normally, the yield issues in the manufacture of medical devices are the responsibility of engineers often with direct responsibility for manufacturing, quality and supplier issues. They will typically manage to optimize the process within the validated range. They are typically judged by their effect on short-term process performance measurements. There is usually insufficient incentive to start the project needed to upgrade the validated prototype process to one more appropriate for full-scale manufacture. The timeframe is too long. The material cost requirements are too high. The engineers often do not have the skills or experience required to validate the process and produce the data needed for regulatory approval.

When engineering effort is applied to improve the process, it is usually related to the skills that are available. If one engineer is particularly interested in automation, for instance, there might be improvement there. Such changes are easy to understand and explain. If they result in reduction of direct labor headcount they are often supported.

Lean Kaizen improvement processes are very popular because they rely on the insight of the people who are most familiar with the process. Industrial engineering teams working with operations staff can improve the prototype process significantly. Lean Principles are useful for getting the best out of the process with minimal risk to the quality or regulatory status of the product.

Automation and lean Kaizen processes can have an unintended negative consequence in addition to positive consequences. They can improve a suboptimal process enough to make the incremental benefit of developing a much better process significantly less attractive. However, in many cases automation and lean Kaizen are the best resources available and the only feasible process improvement processes for some product manufacturing lines.

Even if process improvements cannot be made, it is a very good idea to make sure that there is a channel of communication to the Research and Development (R&D) and Product Development (PD) teams. The insights into the difficulties encountered at scaleup should be fed back to the process development people. Production management should encourage the R&D and PD management to introduce improvements when validating new processes for new products.

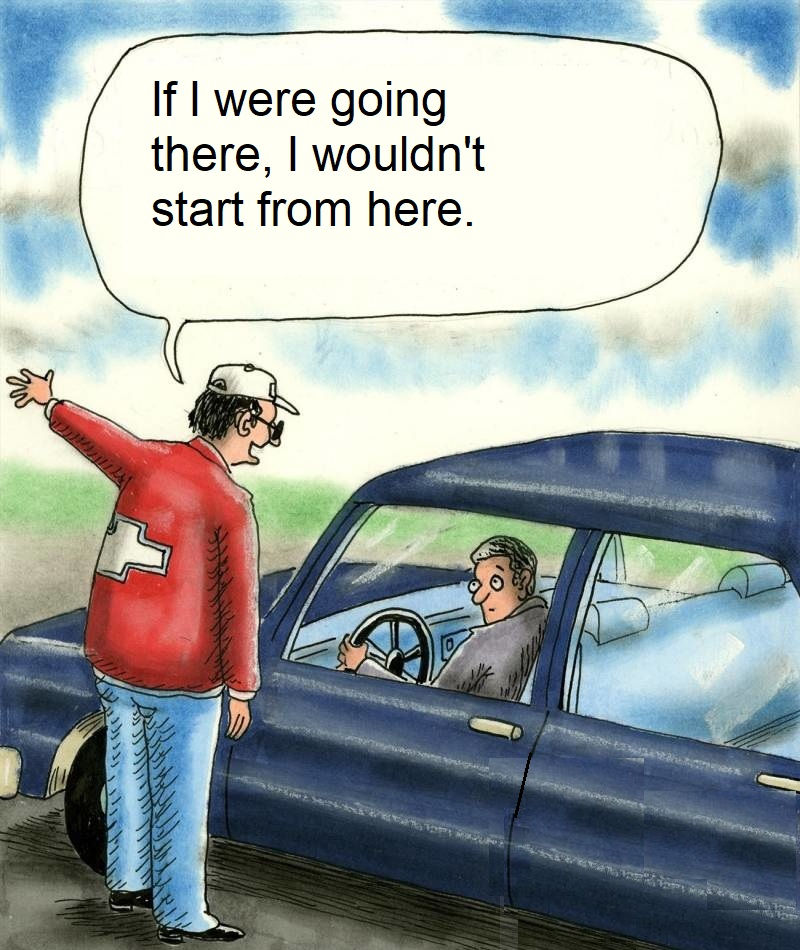

It is a better approach when the R&D developers remain involved throughout the entire process development cycle and become familiar with difficulties that occur at scale-up. Product development should be considered more like ‘rugby’ when the developers continue to run in support of manufacturing after passing the ball instead of stopping, as is often the case, in the ‘relay’ approach often taken to process development (Nonaka and Takeuchi). Frequently, one hears of a new product process being ‘thrown over the fence’.

As stated above the R&D teams will often cite time pressures endangering the development schedule as the reason for not taking on more of the concerns of manufacturing. The companies with best practice develop systems to overcome this conflict with priorities.

This is the introduction to my book available from Amazon.

Comments